If you want a top-quality sprinkler system installation, we’re the ones to call. More broadly, we advise against DIY installations because building a sprinkler system that’s effective, efficient, and up-to-code is labour-intensive and complicated. But if you’ve set your heart on a DIY sprinkler system, the best we can do in that case is be your trusted source for irrigation information.

(Of course, no matter who built your system, if you’re anywhere near Calgary, AB, we’re happy to provide our full suite of services to help make it last, including diagnostic inspections and winterizations.)

After all, we know that building a sprinkler system is a blast. We do it all the time! But unfortunately, DIY doesn’t always mean you can do it all yourself. If you want to keep your home up-to-code, then the most common setup for a DIY sprinkler system just won’t cut it anymore. At the very least, we urge you to have a professional install a backflow preventer and extend a mainline for your system.

While the parts you’ll need for the old-fashioned hose bib setup (AKA garden tap if you’re confused, or boiler drain if you’re not confused enough) are readily available, we simply can’t endorse them. For the sake of conserving water, here’s why we advise against this method for underground sprinkler systems.

1. Hose bib vacuum breakers are insufficient backflow preventers for an irrigation system

This is the big one.

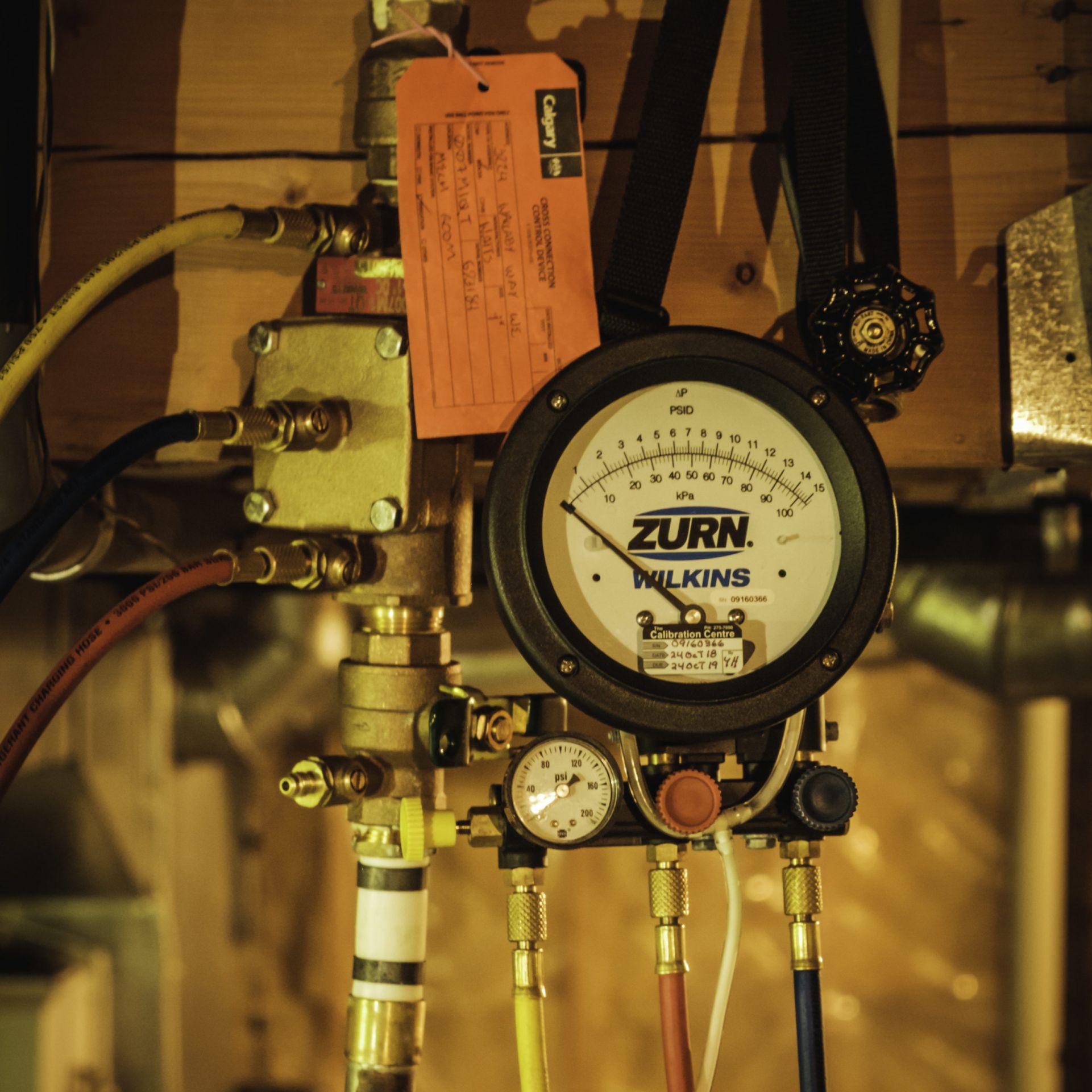

For the sake of potable water everywhere, we stress the importance of backflow prevention for sprinkler systems. A pressure vacuum breaker (PVB) is the type of backflow preventer often recommended for an outdoor faucet, and for a long time they were the go-to for irrigation as well. However, they are only designed to prevent one kind of backflow: siphonage, not backpressure.

Siphonage is a drop in pressure at the water source, effectively creating a pressure vacuum that pulls water back. Without getting into the engineering side of things, you can probably guess that this is where the pressure vacuum breaker shines. Backpressure, on the other hand, is when an external system temporarily exerts more pressure than its source. Spray nozzles, conventional sprinklers, and other typical uses for a garden hose are unlikely to exert backpressure. However, underground sprinklers can make no such promises.

Additionally, pressure vacuum breakers are untestable, and many consumer-grade versions are unreliable. There’s no way to know if it’s working unless you actually see it venting water during a backflow event. Otherwise, you would have no idea that anything’s happening. There’s no point in having a backflow preventer that, for all you know, might not be preventing backflow. At the very least, you may want something testable just to satisfy your municipality’s testing requirements.

Most modern irrigation systems have a double check valve assembly (DCVA), and it’s what we normally recommend. Also, certified technicians must install these devices. That’s why we recommend you at least contact a plumber first if you really, really want to build your own sprinkler system.

2. Hose bib connectors always leak eventually

While a proper backflow preventer is needed to bring a system up-to-code, there are endless other considerations to making it efficient and effective. Many of these essentially boil down to making sure it doesn’t leak.

If you look into the tap-end of your garden hose, you’ll see a rubber gasket (AKA O-ring). If you’ve had the hose for more than a year, you’ll probably see cracks and notches beginning to form. Even if you’ve invested in the cutting edge of garden hose technology, that gasket is going to leak someday.

Normally, you’d be quick to notice when your hose is leaking and replace it – or just the O-ring, if you’re a savvy consumer. After all, most homeowners know to turn off above-ground sprinklers or spray guns by closing the garden tap. But if the hose runs from the tap to an underground system, with an automated timer somewhere in between, a leak could go unnoticed for weeks. Such is the double-edged sword of set-it-and-forget-it. All automated systems need to be designed and constructed with great care.

Given where most garden taps are installed, you also risk more than some wasted water if the leak goes unnoticed for long enough. In the worst case scenario, a persistent leak inches away from your house could mean unthinkably expensive repairs – if you’re lucky.

3. Hose splitters break sooner if they’re unevenly balanced

This is one of those things. One of those things most people outside of your industry would never think of, and by the time you think of it, maybe it’s time to use some of that vacation time you’ve accrued.

Admittedly, it’s also a relatively minor thing, which is why it’s nestled here in the middle of the article.

Hose splitters, Y-valves, or manifolds if there are several outlets, hang unsupported when connected to a garden tap. A permanent connection on just one side will constantly pull it in that direction. Gravity will always pull straight down, but an imbalanced load adds a small lateral force. That’s fine if you’ve just connected a hose – that’s what it’s for. But, add an electronic timer valve and a pressure vacuum breaker (which we’ll get to later), and the strain is increased. It may still take years to create a problem, but fewer years than it should. And when it does, you once again have water wasting in a bad spot.

4. Every inch of hose restricts your system’s water flow

A leak isn’t the only way for your sprinkler system to lose pressure.

Dynamic pressure – the kind we’re concerned with at the nozzle – is reduced by the friction of water moving across the inner walls of a tube. If the pipe is too long, or its diameter too small, the friction loss increases.

Technically, this applies to any hose or pipe. For example, even municipal water mains can fail to supply enough pressure for a sprinkler system. If you’re unlucky enough to be too far from your neighbourhood’s pumping station, it might not be doable. But for the vast majority of homes, underground sprinklers are viable as long as they’re economically designed. When Naiad installs your lawn sprinklers, we use 1″ pipes everywhere we can. 3/4″ is the standard for most irrigation contractors, but bigger is better.

The problem with feeding your underground sprinklers from a garden hose is that it’s almost always 1/2″ in diameter. If you’re only watering a small area like a flower garden, and it happens to be fairly close to the spigot, this might be a non-issue. But if you want lawn sprinklers, mitigating friction loss anywhere possible is sometimes necessary for effective coverage. With insufficient pressure, a sprinkler system may even appear to work, but it will take weeks to notice that your nozzles aren’t spraying as far or evenly as they’re meant to.

And, speaking of coverage…

5. Most properties will need multiple “zones” in a sprinkler system

As with hose diameter, this might not be an issue if you just want to take care of your tomatoes. But if you want to irrigate your lawn, they’ll need to cover a much wider area. The problem is that you’re working with finite pressure. Having too many nozzles on a line will spread that pressure too thin. With insufficient pressure, a nozzle can’t cover the area it’s designed to. You might think of adding more nozzles to cover smaller areas, but that only means more openings.

The solution is to divide the system into “zones” and run them separately. For example, a truly vast lawn might need twenty sprinklers for full coverage, but the plumbing can only run five. An installation contractor would install four control valves, each to run five heads at a time. A programmable timer could then run the four zones consecutively, instead of simultaneously.

Separating a sprinkler system into zones can also help it run more efficiently. Grass on different slopes or elevations, in sunny or shady spots, or even in proximity to certain landscaping features will have different watering requirements. You can water less needy areas for a shorter time if they’re controlled by a separate valve.

The problem with the classic hose bib setup is that it’s much harder to manage multiple zones. With sufficient finagling, you could attach multiple timed valves to a manifold. However, it’s much more convenient to just have one programmable timer wired to multiple control valves.

So, what do we recommend?

Above all, we recommend a professional installation. Unfortunately, even if every nozzle has optimal pressure, and nothing leaks, there’s still more to making a sprinkler system efficient. We touched on it briefly in the last section: different areas will have different watering needs. The depth of that rabbit hole, though, is absurd. Slope, elevation, shade, landscaping features, soil composition, local climate, type of grass, root depth… It’s all best left to a Certified Irrigation Designer.

But because it feels good to work with your hands, we get that you may be in it for the constructing, not just the watering. Hobbies exist, and that’s okay. In which case, our basic recommendations are as follows:

- Instead of overburdening your garden faucet, at least have a backflow preventer, isolation valve, and mainline installed by a professional.

- While we don’t recommend feeding the system from your existing garden tap, having a couple installed in your system will be convenient for winterizations if you live in a cold climate. We recommend:

- One on the mainline inside to act as a drain

- One on the mainline outside to connect an air compressor

- Divide your watering area into manageable zones, separated by watering needs if necessary. Control the zones with a single, programmable timer.

- Use contractor-grade parts only and know their specifications.

- The minimum for professional maintenance is a cross connection test and a winterization (in cold climates) every year.

And for a few extra details, here are a couple videos of ours with suggested features for installations:

Book a service or call us today @ 587-200-3994. We provide top-notch services from Irrigation Association-certified professionals.